Application for split core current transformers

Jan 19, 2026The core advantage of the Split Core Current Transformer is that it can be installed by clamping without disconnecting the circuit under test, and it is compatible with various on-site conductor sizes. Therefore, it is widely used in scenarios requiring rapid deployment, non-stop machine modification, and temporary monitoring. Specifically, it can be divided into the following five categories:

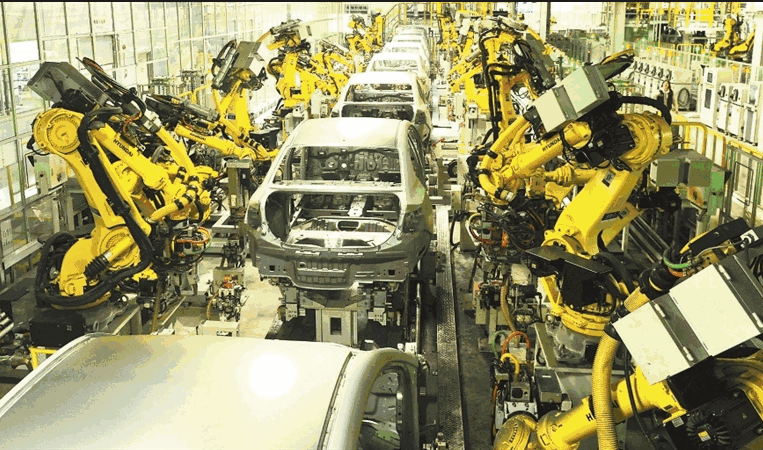

1.Industrial equipment modification and operation and maintenance monitoring, applicable to current monitoring and energy consumption analysis of factory production lines, motors, frequency converters, air compressors, and other equipment.

Without the need for downtime or power shutoff, it can be directly clamped onto the busbar or cable, thus avoiding production interruptions.

It can monitor equipment load rates in real-time, prevent overload failures, and optimize equipment operation efficiency.

Typical scenarios: upgrading the energy consumption system of old factories, and early warning of current anomalies in production line equipment.

2.Commercial buildings and building energy management are core components of the Building Management System (BMS), used for sub-itemized energy metering and energy-saving control.

Conduct sub-metering for circuits such as lighting, air conditioning, and elevators in office buildings, shopping malls, and hotels, and calculate the energy consumption proportion of each system.

Support the on-demand adjustment of the operating status of electrical equipment to reduce overall operating costs.

Typical scenarios: energy consumption audit of commercial complexes, and intelligent power management and control of office buildings.

3.The grid-connected monitoring system for new energy power generation is compatible with grid-connected current monitoring and data acquisition for distributed power generation systems such as photovoltaic and wind power systems.

Monitor the inverter output current to ensure stable grid-connected current and compliance with grid access standards.

It can be used in conjunction with energy storage devices to achieve precise metering and control of charging and discharging currents.

Typical scenarios: grid-connected monitoring of rooftop photovoltaic power stations, and current data acquisition of small wind farms.

4.Temporary inspection of power systems and utilities is used for on-site inspection, fault diagnosis, and temporary metering by power operation and maintenance personnel.

Conduct temporary current detection on the outgoing lines of distribution networks and substations to quickly locate the fault point.

Replace traditional through-type CTs, shorten maintenance time, and enhance operation and maintenance efficiency.

Typical scenarios: fault current monitoring during power emergency repairs, and load survey of distribution networks.

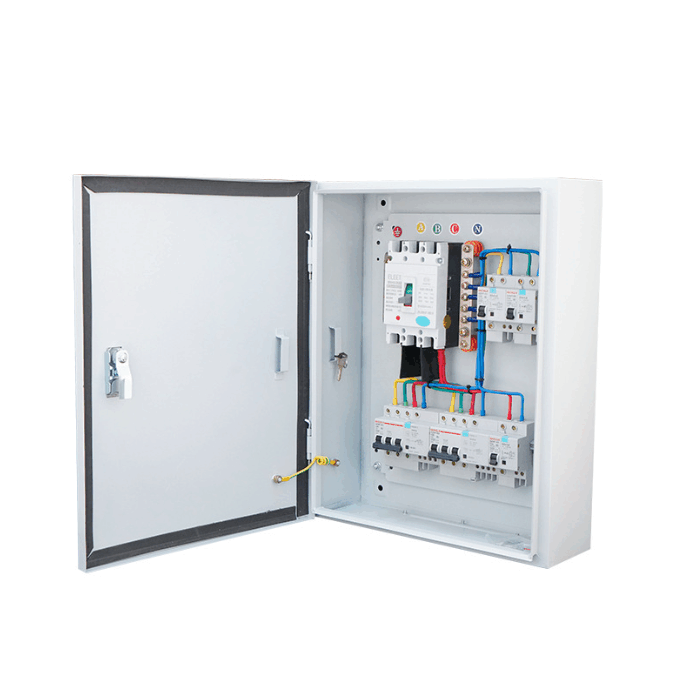

5.The power supply guarantee for data centers and communication base stations focuses on high-reliability power supply scenarios. It monitors the output current of UPS and distribution cabinets to ensure stable operation of equipment.

Monitor the power supply current of data center cabinets in real-time to prevent equipment downtime caused by overload.

It is suitable for outdoor installation environments of communication base stations, withstanding harsh conditions such as high and low temperatures, humidity, etc.

Typical scenarios: power distribution circuit monitoring in large data centers, and power supply current monitoring in 5G base stations.